-

BeutelVerpackungsmaschine

-

Körnchen-Verpackungsmaschine

-

flüssige Verpackungsmaschine

-

PulverVerpackungsmaschine

-

Mini Doypack Packaging Machine

-

Teebeutel-Verpackungsmaschine

-

KaffeeVerpackungsmaschine

-

vertikale Verpackungsmaschine

-

Fluss-Verpackungsmaschine

-

Stehen Sie oben Beutel-Verpackmaschine

-

Vakuumverpackende Drehmaschine

-

Füllmaschine

-

Horizontale Doypack-Verpackungsmaschine

-

Premade-Tasche

-

Verpackungsmaschine-Zusätze

-

mit einer Leistung von mehr als 100 W

Pet Produkt Verpackungsmaschine für Katzenstreu, Katzenfutter, Hundefutter, Leckerlis, Gefriergetrocknete Produkte mit Staubentfernungsgerät

| Herkunftsort | Guangdong , China |

|---|---|

| Markenname | ZCHONE PACK |

| Zertifizierung | ISO,CE |

| Modellnummer | ZC-8200 |

| Min Bestellmenge | 1Set |

| Preis | $18000 |

| Verpackung Informationen | Standard -Export -Holzfallverpackung |

| Lieferzeit | 15 |

| Zahlungsbedingungen | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Versorgungsmaterial-Fähigkeit | 1/sets/15day |

| Typ | Automatische Verpackungsmaschine | Produktname | Verpackungsmaschine mit Multi-Station-Verpackung von Lebensmitteln |

|---|---|---|---|

| Dimension (l*w*h) | L1900*W1400*H1450 | Gewicht (kg) | 1300 |

| Stromspannung | 110 V 220 V 380 V 50 Hz/60 Hz | Produktionskapazität | 20 Bag/min, 50 Bag/min, 30 Bag/min |

| Hervorheben | Katzenstreu-Verpackungsmaschine mit Staubentfernung,Hundefutter-Verpackungsmaschine für gefriergetrocknete Leckerlis,Granulat-Verpackungsmaschine für Tierprodukte |

||

| Packing Machine Type | |

|---|---|

| Granule Packing Machine | |

| Liquid Packing Machine | |

| Powder Packing Machine | |

| Stand-Up Pouch Packing Machine | |

| Vertical Packing Machine | |

| Horizontal Packing Machine | |

| Tea Bag Machine | |

| Coffee Bean Packing Machine | |

| Horizontal Packing Machine |

Verpackungsmaschine für Tierprodukte für Katzenstreu, Katzenfutter, Hundefutter, Leckerlis und gefriergetrocknete Produkte mit Staubentfernungsvorrichtung

Die "vorgefertigte Beutel-Katzenstreu-Verpackungsmaschine" ist ein entscheidendes und gängiges Ausrüstungsteil in der Herstellung von Tierbedarf. Sie ist speziell dafür konzipiert, verschiedene Arten von Katzenstreu, wie Bentonit, Tofu-Streu, Kristallstreu und Mischstreu, automatisch in vorgefertigte Verpackungsbeutel zu füllen.

I. Was ist eine vorgefertigte Beutel-Katzenstreu-Verpackungsmaschine?

Dies ist eine automatische Verpackungsvorrichtung, die vorgefertigte Beutel verwendet, oft mit einem wiederverschließbaren Reißverschluss (Standbodenbeutel) auf der Rückseite. Der Arbeitsablauf ist wie folgt: Beutel aufnehmen -> Beutel öffnen -> Füllen -> Verdichten (optional) -> Luft absaugen / Versiegeln -> Fertigprodukt ausgeben.

Sie arbeitet nach einem ähnlichen Prinzip wie eine andere gängige Maschine, die "Beutel-Zuführ-Verpackungsmaschine", ist aber für die Eigenschaften von Katzenstreu (wie Staub, unterschiedliche Partikelgrößen, instabile Schüttdichte usw.) optimiert.

II. Hauptmerkmale und Vorteile

1. Ästhetisch ansprechende Verpackung: Vorgefertigte Beutel sind oft exquisit bedruckt und können direkt als Verkaufsverpackung verwendet werden, mit einem attraktiven Aussehen, das die Qualität des Produkts erhöht.

2. Hoher Automatisierungsgrad: Der Prozess von der Beutelaufnahme bis zur Fertigproduktausgabe ist vollautomatisch, was erheblich Arbeitskräfte spart und die Produktionseffizienz verbessert.

3. Reißverschluss-Verschließfunktion: Dies ist eine wesentliche Funktion für die Katzenstreu-Verpackung. Die Maschine öffnet und heißversiegelt den Reißverschluss präzise, wodurch die Dichtigkeit gewährleistet und die Mehrfachverwendung für den Verbraucher erleichtert wird.

4. Starke Anpassungsfähigkeit:

Beuteltypen: Kann verschiedene Beuteltypen wie Standbodenbeutel mit Seitenfalte, Vier-Seiten-Siegel-Standbodenbeutel und Griffbeutel verarbeiten.

Materialien: Durch den Wechsel verschiedener Zuführvorrichtungen (wie Schneckenzuführung, Schwerkraftzuführung, Vibrationszuführung) kann sie sich an Katzenstreu mit unterschiedlichen physikalischen Eigenschaften wie Bentonit-Granulat, lange Tofu-Katzenstreu-Streifen und feinen Kristallsand anpassen.

5. Integrierte Verdichtungs- und Luftabsaugfunktionen:

Verdichtung: Vibriert den Beutel, um die Streu im Inneren zu verdichten, ein Aufblähen des Beutels während des Transports zu verhindern und eine dichtere Verpackung zu ermöglichen.

Luftabsaugung: Eine Luftabsaugvorrichtung kann optional ausgestattet werden, um die Luft aus dem Beutel zu entfernen, wodurch die Verpackung kompakter wird und Lager- und Transportraum gespart wird, besonders geeignet für Bentonit-Streu.

6. Präzise Dosierung: Verwendet hochpräzise elektronische Waagen (z. B. Wäge-Füll-Typ) oder volumetrische Dosierung, um ein gleichmäßiges Gewicht pro Beutel zu gewährleisten und den Handelsspezifikationen zu entsprechen.

III. Grundlegender Arbeitsablauf

1. Beutelbeladung: Ein Roboterarm nimmt automatisch einen vorgefertigten Beutel aus dem Beutelmagazin auf.

2. Beutelöffnung: Verwendet Saugnäpfe oder Greifer, um die Beutelöffnung zu öffnen und über der Fülldüse zu platzieren.

3. Füllen: Die abgemessene Katzenstreu fällt durch die Fülldüse in den Beutel.

4. Verdichtung/Nivellierung: Während oder nach dem Füllen verdichtet und nivelliert eine Hochfrequenzvibration die Streu.

5. Luftabsaugung (optional): Wenn diese Funktion konfiguriert ist, wird die Luft im Beutel in dieser Phase entfernt.

6. Heißsiegeln: Die Beutelöffnung wird heißversiegelt, einschließlich der inneren Reißverschlussversiegelung und der äußeren Beutelöffnungsversiegelung.

7. Ausgabe: Der fertige, versiegelte Beutel wird über ein Förderband ausgegeben und kann mit einem Etikettierer oder Codierer verbunden werden, um das Datum/die Chargennummer aufzudrucken.

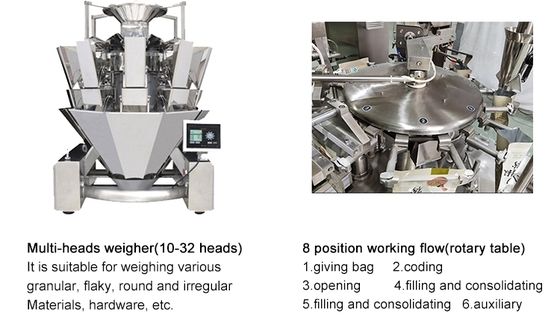

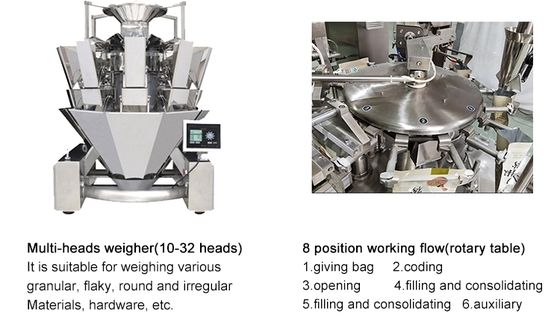

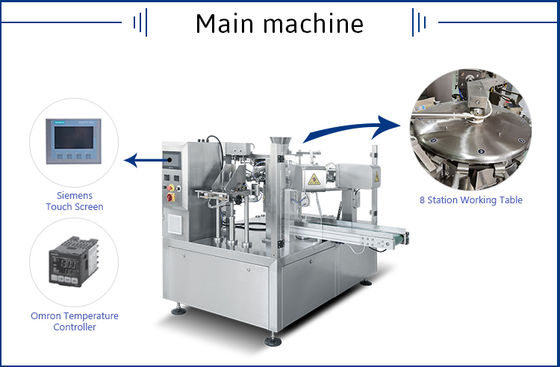

IV. Wichtige Gerätekomponenten

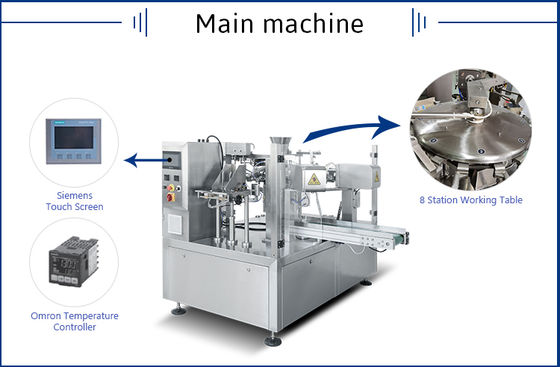

1. Hauptrahmen & Steuerungssystem: SPS + Touchscreen-HMI, das Gehirn der Ausrüstung.

2. Beutelbeladungsmechanismus: Servomotorbetriebener Roboterarm, der für die präzise Beutelaufnahme und -öffnung zuständig ist.

3. Dosiersystem: Oft eine Wäge-Füll-Trichterwaage, die höchste Genauigkeit bietet und sich an Änderungen der Schüttdichte der Streu anpasst.

4. Füllsystem: Enthält einen Vorratstrichter, einen Zuführmechanismus (z. B. Schnecke, Tor) und ein staubdichtes Design.

5. Verdichtungsvorrichtung: Hochfrequenzvibrator, normalerweise unterhalb oder seitlich der Füllstation angeordnet.

6. Luftabsaugsystem: Vakuumpumpe und Saugdüse.

7. Heißsiegel-System: Heizplatte und Kühlplatte, um eine sichere Versiegelung sowohl für den Reißverschluss als auch für die Beutelöffnung zu gewährleisten.

8. Förderband: Verbindet verschiedene Arbeitsstationen und transportiert Beutel und Fertigprodukte.

Maschinenspezifikation:

| Artikel | ZC-X8200 | ZC-X8250 | ZC-X8300 |

| Verpackungs-Geschwindigkeit | MAX 60 Beutel/min, abhängig von der Qualität der Verpackungsfolie, den Verpackungsmaterialien, dem Verpackungsgewicht usw. | ||

| Beutelgröße | (L)100-300mm (B)70- 200mm | (L)100-350mm (B)130- 250mm | (L)150-450mm (B)200-300mm |

| Beuteltyp | Vorgefertigte Beutel, Standbodenbeutel, Vier-Seiten-Siegel-Beutel, Drei-Seiten-Siegel-Beutel, Sonderformbeutel | ||

| Wiegebereich | 10g-1kg | 10g-2kg | 10g-3kg |

|

Mess- Genauigkeit |

*≤±0,5~1%, abhängig von der Messausrüstung & Materialien. | ||

| Maximale Beutel- Breite | 200mm | 250mm |

300mm |

| Gas- Verbrauch | 0,8Mpa 0,3m3/min (Bereitstellung durch den Benutzer) | ||

| Gesamt- Leistung/Spannung | 2,5KW 380V 50/60Hz | 2,5KW 380V 50/60Hz | 3,7KW 380V 50/60Hz |

| Luftkompressor | Nicht weniger als 1 CBM | ||

| Abmessung | L1900*B1400*H1450 | L1900*B1400*H1450 | L2000*B1500*H1550 |

| Maschinengewicht | 1300kg | 1400kg | 1500kg |

| Arbeitsablauf | Beutel geben→Codieren→Beutel öffnen (oder Reißverschluss öffnen)→Füllen→ Hilfsmittel→Abluft→Heißsiegeln→Formen und Produkte ausgeben. | ||

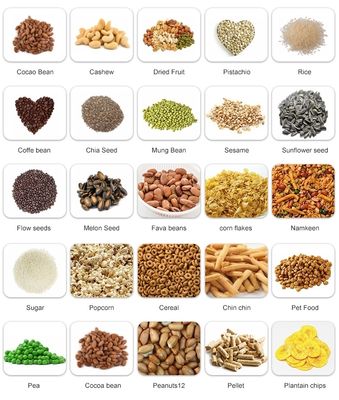

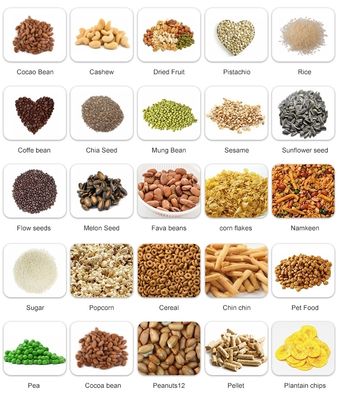

| Anwendungsbereich | Granulartyp: Kristall-Mononatriumglutamat, Granulatmedikamente, Kapseln, Samen, Chemikalien, Zucker, Hühneressenz, Melonenkerne, Nüsse, Pestizide, Dünger usw. | ||

(Wir können Ihnen exklusive, kundenspezifische Dienstleistungen nach Ihren Bedürfnissen anbieten!)

![]()

![]()

![]()

![]()